Whenever you cut mortises with a slot mortiser, you end up with mortises that are round on each end . So you need a tenon that has a similar round for perfect fit .

I used to always cut these on the table saw and then cut them round with the hand saw .But I’ve invented a new machine that cuts these with the rounded ends on both sides .

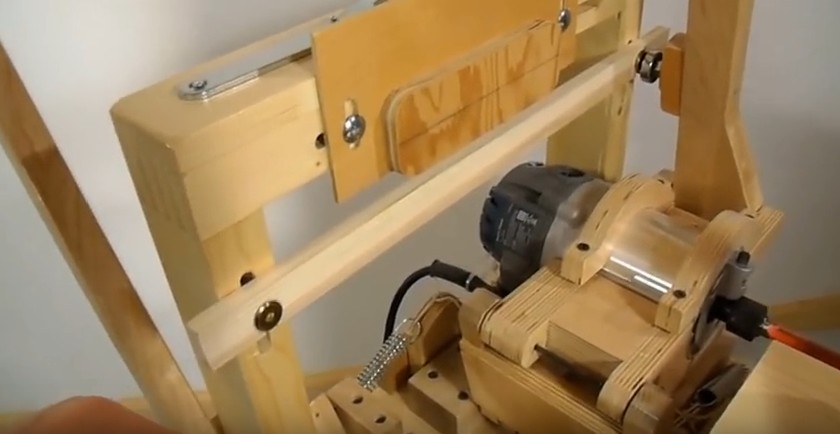

I call my new machine the pantorouter because it uses a pantograph mechanism to allow this router to follow the motion of this ball bearing.

The pantograph is a 2 to 1 reduction mechanism . It takes the motion of the ball vearing and cuts it down by a factor of two so that my router bit always follows the exact same shape . The path that my ball bearing follows but half the size. So , to make a tenon.

What I need is a template that’s exactly twice the size of my tenon and then follow that all way around with the ball bearing and my router bit will cut the perfect shaped tenon off the stock that’s placed .

I can also use this machine to cut mortises . All I need is a straight track for the bearing to roll back and forth on and my router bit will also follow a straight path .

With different templates I can cut different types of joints .

With the corresponding multiple mortise template , I can do a triple mortise to go along with that triple tenon .

The cool thing with this machine is I only need to get my fit with the templetes , right just once . And then I can make as many joints as I want to and they all fit perfectly .

The possibilities with a machine like this are nearly endless . With this templete here for example I can cut integral dowels at the end of a piece of stock .

How the Pantorouter works ?

The Template gets mounted and then the router follows the exact same shape of the template so this allows the machine to reproduce any shape of template on the stock at one half scale .

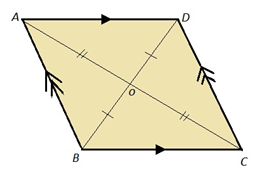

I’ve constructed this simple mechanism to show how a pantograph actually works .

If you look on image above , you’ll notice these two parallelograms are the same size and they always share the same angle . Which means that this distance is always equal to that distance .

That means, if I hold one point fixed and trace out a shape with that point , the intersection will trace out the exact same shape but at half the scale .

But, this mechanism actually has some redundant links in it . So, removing those you can still see it behaves the same way.

Ok, now looking at the back of the machine you can see essentially the same pantograph mechanism that I showed on my workbench .

I’d use the same kind of steel pins for hinges on my quickset tenon jig and that’s worked out very well . I get really good reproducibility on this machine .

When I was experimenting with the prototype for the mechanism , I found that was a little bit tired to always have to pull up by the handle to compensate for the weight of the router . So, what I added is these springs here and this cam shape .

And that, essentially compensates for the weight of the router across this ranger of motion .

I added a similar spring on the other side so this spring compensates for the long link . And the other spring for the short links .

Now, if you want to use this machine to carve an internal cavity such as a mortise ,

I need to be able to plunge into the cavity and I’ve added, essentially a plunge sled on here . This lever operates the sled and this part here essentially moves the whole back half of the machine on side .

In case this machine can’t make you happy , you can use router table like this model bench dog promax or some products of this kreg router table branch in lieu of this pantorouter machine .