Finding the right variant is of prime concern as soon as choosing a ladder comes under concern. The standard materials that are used for making ladders are fibreglass, wood and aluminum. Though all these ladders serve its purpose, aluminum and wood are subject to corrosion. The fibreglass ladders are lower conductors of electricity. They do not even succumb to the elements. They are thus, the best options to be used both at home as well as workplace.

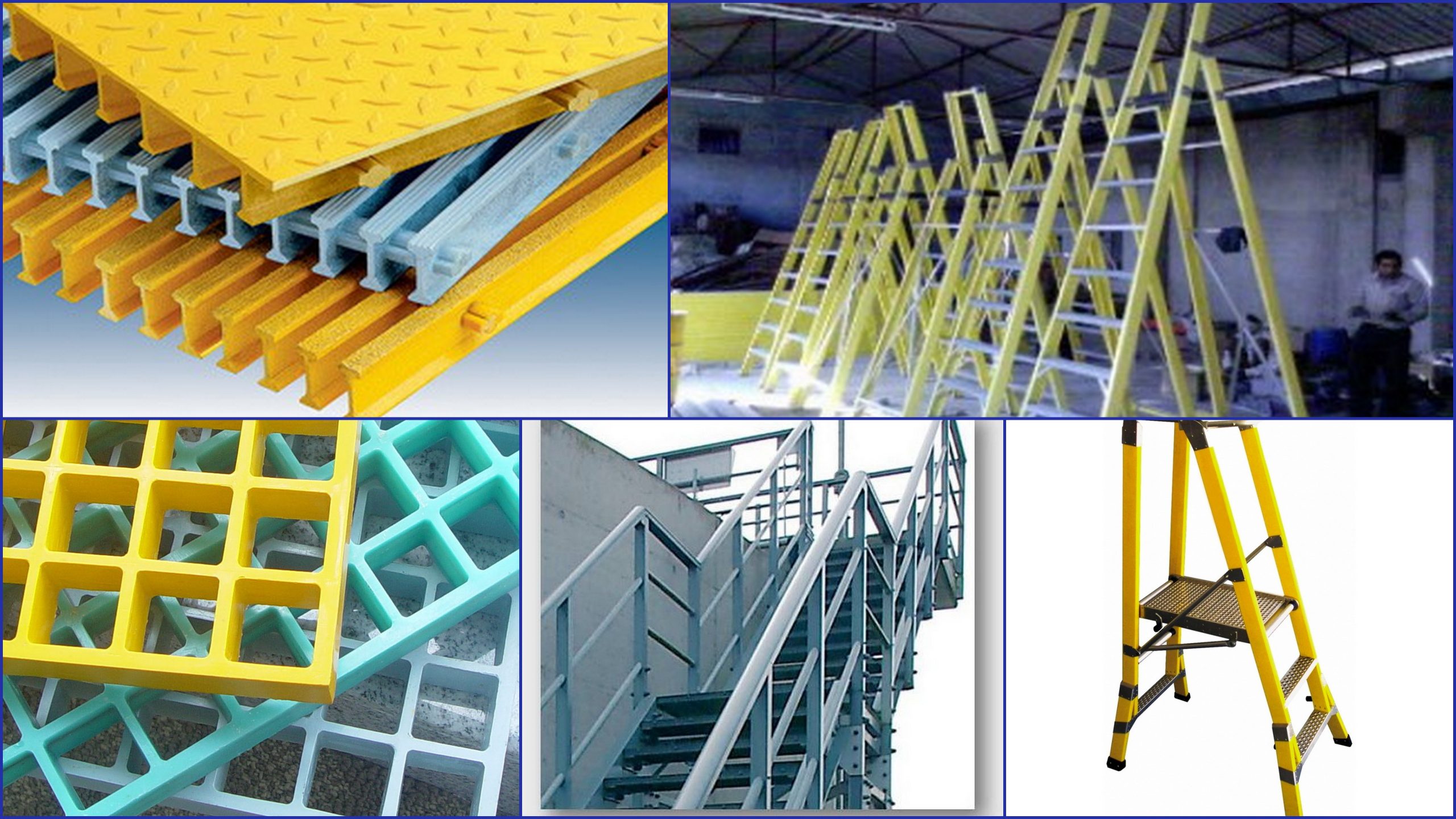

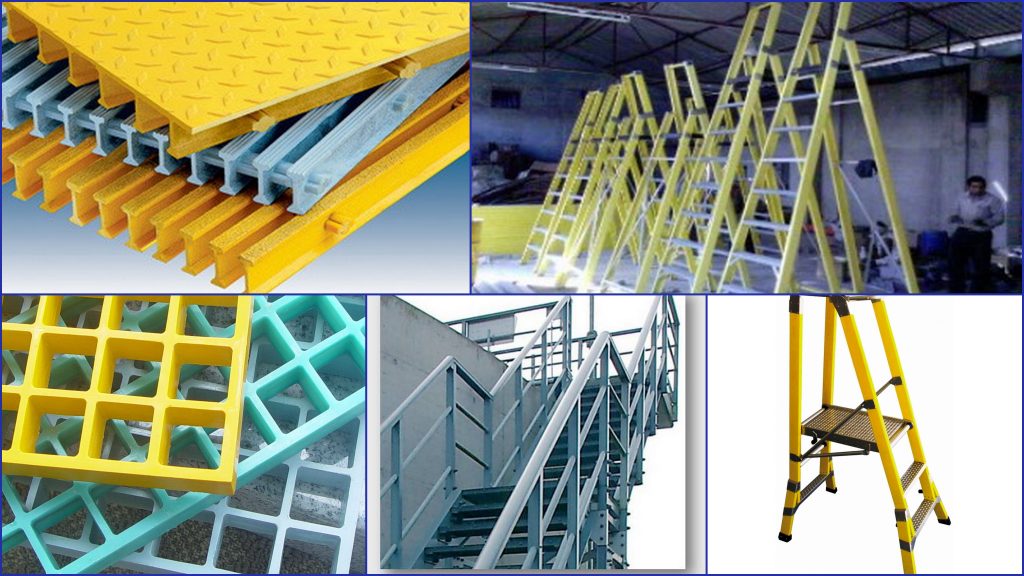

Multiple Advantages of Fibre Glass Ladder Usage:

As compared to various other building materials, fibreglass enjoys longer life expectancy since they are non-corrosive in nature. Even in a harsh environment, they can function much better than wood, metal or plastic. It is a popular option because it can tolerate exposure to unkind environment. Moreover, it also offers resistance to intense temperatures, salty air and ultraviolet rays. It is corrosion resistant and chemically inert and thus they are more advantageous as compared to wood or aluminum. The biggest advantage that it has over the aluminum counterparts is resistance to electricity. Since they do not conduct electricity, they are safer to use around the power lines. These ladders also possess high flexural strength and high strength to weight ratio. This appealing lightweight material directly builds strength into any component.

More Beneficial than Wooden Ladders:

As the fibreglass ladders involve usage of man-made material, it has an advantage over the wooden ladders. The natural materials like wood may have significant variations in quality and thus the weaker wooden ladder rungs or support beam can fall off without any warning. The beams made of fibreglass are strong and uniform. Though aluminum is comparatively more consistent than wood, different manufacturers use up different grades of aluminum. The cheap ladders can bend under heavy load.

Resistant to Bad Weather Conditions:

Most construction workers find fibreglass to be more resistant to the bad weather conditions. The wooden ladders can rot after some cycles of dry and wet exposure. Fibreglass does not absorb moisture or weaken significantly when exposed to Sun.

Can Resist Flames:

The fibreglass ladders can resist flame, thereby making it ideal for the firefighters scaling the buildings. This material may catch fire if placed directly under a heat source, but it will get extinguished by self as soon as the source is removed. Though the aluminum ladders are comparatively more flame resistant as compared to wood, they may conduct electricity transferred by water.

Extremely Robust and Strong:

The ladders made of fibreglass are robust and strong. They offer resistance to twisting and denting. Low maintenance and consistency in quality are chief characteristics of these ladders. Thus, they are more cost effective as well.

The fibreglass ladders offer a much more durable alternative to natural wood and they are a comparatively safer alternative to aluminum. The workplace accidents are quite common and every year, a number of workers get handicapped or even pass away owing to this. These accidents chiefly take place owing to incorrect selection of ladder. Safety must be taken into consideration before making investment in ladders. Remember that most accidents are caused due to unstable ladders or electrical shocks. This can be easily prevented through usage of the fibreglass ladders.