Manufacturing businesses need to know that their machinery and employees are working at maximum capacity and that they are achieving all of the targets that have been set out by the company.

If you run a business, you might be unsure about how performance can be measured effectively. This is especially true if you are an inexperienced manager with a relatively new business. The Overall Equipment Effectiveness System will allow you to collect hard data about the performance of your machinery as well as the performance of your employees.

There are several reasons why installing this kind of system is a very good idea for your business.

The Layout Is Extremely Easy To Understand

When you have to deal with complicated databases which are loaded with information, you might struggle to pick out the key performance indicators which highlight how efficiently your equipment and employees are performing. This can be frustrating and will make you feel that you are wasting precious time. If you are not able to use the expensive software correctly, you will also feel like you have wasted the company’s money on something which is inefficient.

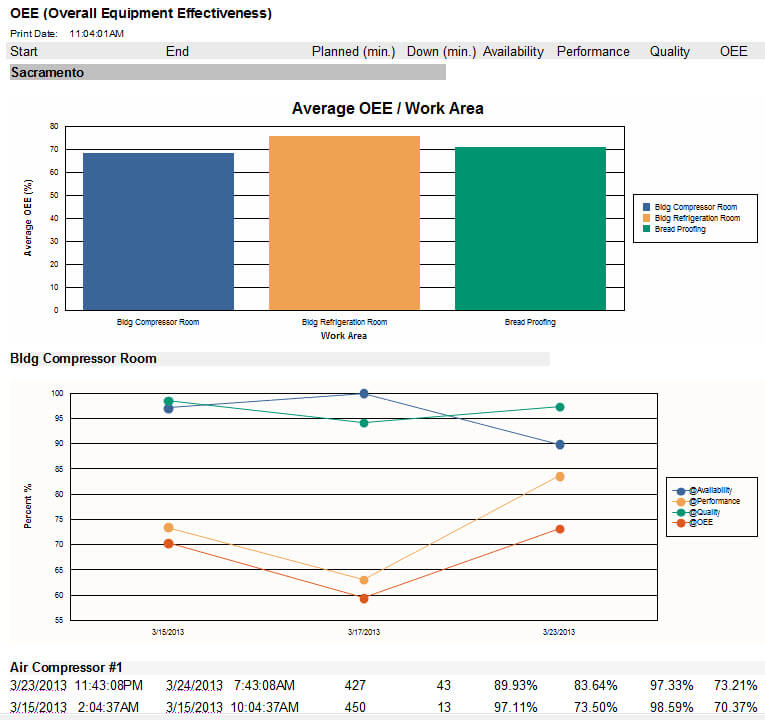

OEE systems have a very simple layout which is divided into clear sections. You will be able to break down and understand all the data extremely easily. This will improve the efficiency of your business and will ensure that you are not wasting time.

The Reporting Is In Real-Time

When you are studying the efficiency of your equipment and employees, the last thing you want to do is wait for results. If you want to be able to solve problems about company efficiency, you need to be able to look at the relevant data in real-time. You will be able to track this information and contrast the efficiency from hour-to-hour and from day-to-day. You will then be able to take decisive action as soon as possible.

The real-time reporting comes in the form of alerts which will tell when there has been a change on the dashboard. These alerts are useful if you are juggling several different tasks at the same time.

Root Cause Analysis

In order to solve problems with efficiency, you need to be able to get to the bottom of the problem as soon as possible. The overall equipment effectiveness system allows you to perform Root Cause Analysis on each of the efficiency problems that occur. The Root Cause Analysis speeds up the problem-solving process and will allow your business to save both time and money.

Improvement Agendas

Once a problem about efficiency has been identified, you will then need to think about ways that this issue can be improved. This is not easy task when you are dealing with lots of other problems. The Improvement Agenda section of the software will give you suggestions about how the efficiency can be improved.

Choosing Overall Equipment Effectiveness Software will streamline your business and will improve the efficiency of both your equipment and your employees.